Capability

Since 1976, NAMCO has dedicated themselves at developing a professional team

with sustainable and competitive manufacturing & repair facilities to meet

the needs of its customers and industries served. We are organized to undertake

any types of projects from inception to completion by making use of the most

advanced manufacturing equipment and technology available today.

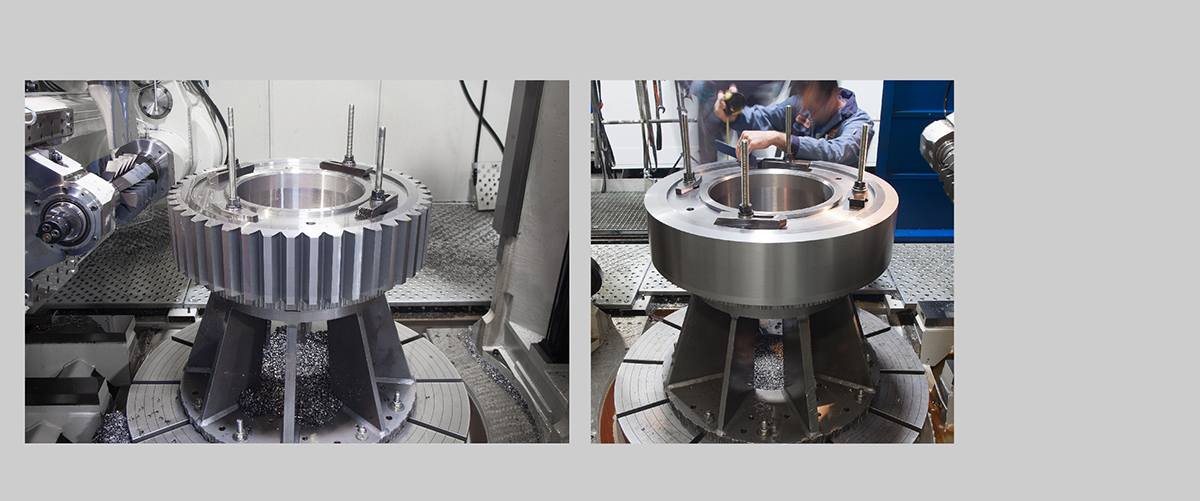

NAMCO has always invested in the future with the latest technologies that include

Engineering & Design software, CNC Automation & Manual machining as well as

welding or fabrication centers. We also use some of the best gearing and grinding

equipment within industry that can manufacture to AGMA Q15 / DIN 1 which is

the highest gearing standards that very few companies in the world can achieve.

We will handle any project and make certain that only the finest equipment

and workmanship are used for our customers' orders. NAMCO's policy of

preventative maintenance, ongoing replacement and upgrading of machine tools

and resources will guarantee constant integrity in all products and services

that we provide.

With over 40 years strong we have provided customers across the world with

innovative products and capabilities to meet their needs for precision

manufacturing with a quality and service commitment. This approach has

led us to over 80,000 square feet of state-of-the-art facilities consisting

Mechanical Department

- Equipped to provide overhaul on a variety of equipment and machinery

- Prototype manufacturing

- Welding and Fabrication c/w Stress Relieving Facility

- Supported with mig, tig, stick equipment and ironworker machinery

- Capabilities include stainless steel, aluminum and cast iron

- Competent skilled staff dedicated to customer service

- Engineering and Design Department

- Supported with 3-Dimensional Mechanical Design

- AutoCAD (Computer Aided Drafting)

- SmartCAM (Computer Aided Manufacturing)

- Gear Design Software

- Finite Element Analysis (FEA)

- Research and development

- Field service consulting

- Professional Engineering (APEGGA Certified)